The Story of Gartex Trends Corporation®

The journey to become India's top rated clothing manufacturer and exporter began in 2005. Started as 3 member and now a mid-size women-owned family run full-service garment manufacturing factory with registered office (HQ) at Nagpur, Maharashtra, India. At Gartex Trends Corporation®, we practice fair working conditions, good respect and above industry wages for our people. We're proud on having safe working environment with ample natural lighting, paying our staff above than the minimum wages and ensuring reasonable working hours.

Gartex Trends Corporation® is a process oriented highly quality conscious clothing manufacturer with great understanding of design technicality, color code, fitment and fall / flow of the outfit on different body types, drapery, cut & finish, tailoring, fabric composition and its relevance to your design, different washing effects, printing techniques and outstanding hand-works which essentially needed for the effective work on your custom design. Be it design process, pattern making, pattern grading, sourcing of fabrics and trims, custom label and tag development, sampling, embroidery (computer and hand), printing (discharge, pigment, screen, digital, block printing etc), smocking, sequins and beads work, sublimation, bringing washing effects on denim - we are the one-stop full-service clothing manufacturer who does all this!

And unlike other big size clothing manufacturing factories, as mid size factory we promise you will NOT feel lost when placing orders with us. We consistently keep in touch with all our clients and every order we do, we make sure our client's are happy not with our quality but other aspect of business such as transparent communication, quick update and hand-holding even after fulfillment of your order at your door-step!

Gartex Trends Corporation follows below given production processes.

Fabric selection is a crucial step in designing a project because fabrics are designed for specific applications, a fabric manufactured for one purpose, may not be adaptable for another use. Therefore selecting the appropriate fabric is only the first step in providing serviceable fabrics for our clients.

Sourcing & Developing Trimming is a vital aspect of the garment industry as it contributes significantly to the final look, feel, and functionality of a garment. Trimmings can be defined as any additional product, besides the main material, utilized to complete a garment, boost its look or supply extra assistance.

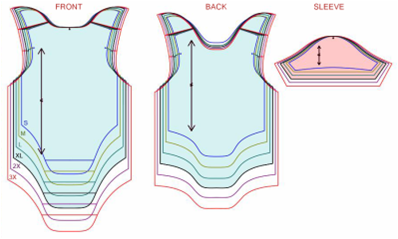

Pattern Making is used as a template to cut out fabric that matches the required specifications to sew a garment. It factors in the type of fabric, the intended fit on the wearer, and any trims that will be used. The pattern is used to make 2D fabric sit properly on a 3D body.

Pattern Grading ensures optimal fit of a garment. We know the significance of pattern grading for producing well-fitting apparel to customers. By meeting the needs of customers with different body shapes and sizes, we are able to build customer loyalty.

Physical Sample of a garment helps the customer check the look, feel, fall, colors and shades, fitting, and the pattern of a certain style.

Garments Dyeing Client can select color code from a wide range of catalogue. We have experience team for getting exact color as required on the fabric.

Garment Printing of all kinds are done by Gartex Trends, it is easier to customer for getting desired designs on their garments

Hand/Computer Embroider & sequence job workof all kinds are done by Gartex Trends, it is easier to customer for getting desired designs on their garments.

Fabric Cutting improves the appearance of the finished product and makes it look well tailored. We are Equipped with modular cutting table to ensure minimum waste.

Stitching play a vital role not just in seam strength, flexibility and appearance, but also in the length of sewing cycles and cost of manufacturing.

Finishing & Quality Control Gartex Trends ensures that the garment is manufactured according to the specifications laid out in the tech pack. Makes sure that the garment is of the right size, color, shape, and quality.

Packaging & Dispatch We take extra care to prevent garments from acquiring wrinkles or creases, during shipping & to minimize storage space for our clients.

Our Vision

To become an end-to-end solution provider to our clients and become the most admired Garment Manufacturer company in terms of quality standards, customer services and workmanship.

Our Mission

We love clothing manufacturing and enjoy working with endless code of colors, fascinating world of fabrics, mesmerizing pattern of print designs, stuns of styles and chaos of meeting deadlines.

Our Values

Customer's satisfaction and delight Superior quality of performance Concern for environment and employee Strive for excellence Fair and friendly to all Safe workplace and healthy work habits.